Home » De-Embrittlement

De-Embrittlement

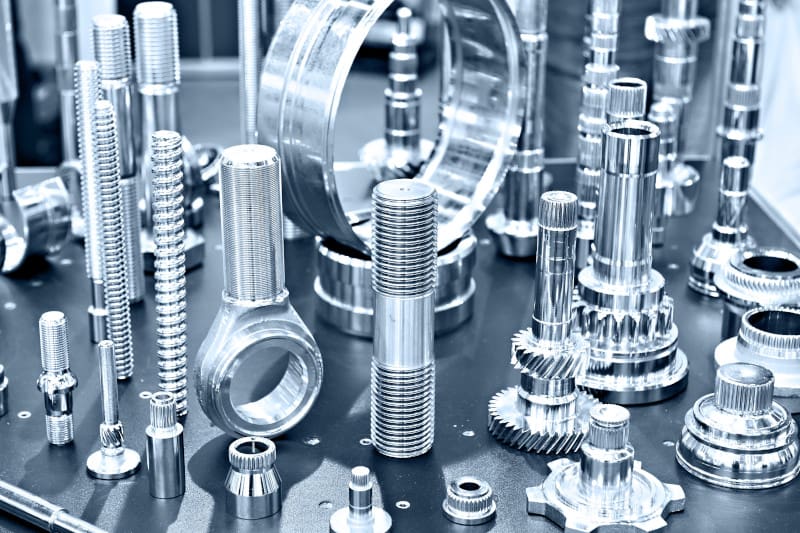

De-embrittlement removes hydrogen gas from the electroplated surface of the product while hardening the metal. This process is essential as the brittle nature of the zinc plating process can cause either fracture or failure of components if the gas is not removed. The process must take place no more than three hours after the electroplating process. We have three de-embrittlement ovens on site and can handle both small and large runs. For more information, get in touch for expert advice and to arrange a free quote for our services.

What is Embrittlement?

The De-Embrittlement Process

De-embrittlement is a heat treatment process that is performed at around 180-240°C. At our metal treatment plant in Smethwick, Birmingham, we have three dedicated de-embrittlement ovens with comprehensive record keeping.

Our Recommendation

With many years of experience, we recommend that components and parts are flash plated before and after the treatment. This can be a more expensive method, however, it ensures that the heat treatment process does not damage the passivate and corrosion protection, while ensuring the finish retains a bright appearance.